Tonsen 11000L brewing equipment arrived in USA, and waiting for the approval for the installation.

A brewhouse may refer to a company that brews beer or the building used for this process, but it’s also a collective term for all the components a brewery will need for the initial brewing stage.

These components typically include the following:Mash mixer,Lauter tun,Hot liquor tank,Boil kettle,Whirlpool.

A larger brewery may use a five-vessel brewhouse, in which each of these components is a separate vessel.

A microbrewery is more likely to use a two-vessel brewhouse that combines the mash mixer, lauter tun and hot liquor tank into one vessel, and the boil kettle and whirlpool into another vessel.

The first of these vessels is used to mash the malt and other grains and extract the liquid wort. The second vessel in a two-vessel brewhouse is used to add hops and other ingredients to the wort and boil the resulting mixture. The wort is then allowed to settle, allowing solid particles to be separated from the liquid.

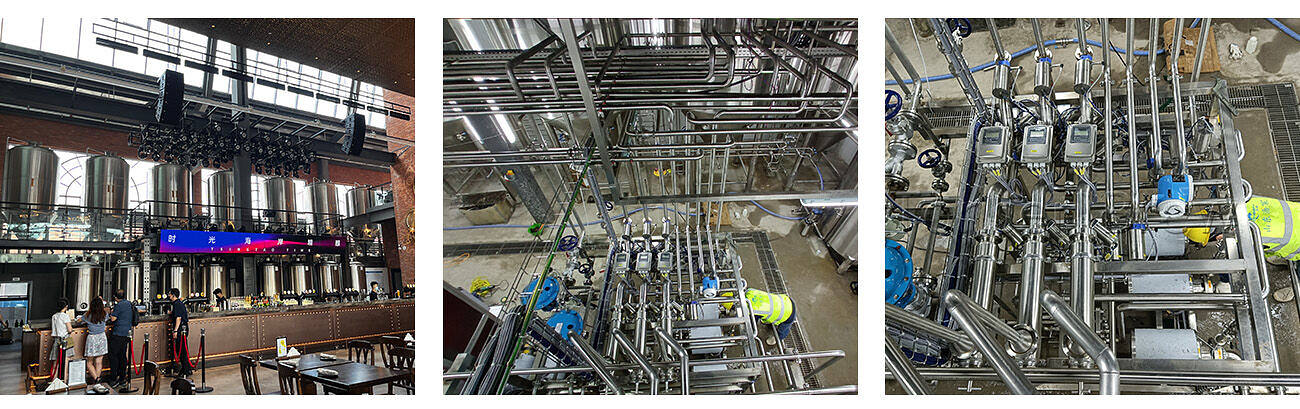

Fermentation Tanks

Fermentation is the next step in the brewing process after the wort has been prepared.

Fermentation tanks hold the wort while yeast converts to sugar in the wort into alcohol and carbon dioxide. These tanks should have a cone-shaped bottom, which facilities the process of recovering the yeast for later use.

Jacketed fermenters allow you to control the mash temperature more easily, but they’re also considerably more expensive.

Brite Tanks

Beer is filtered and pumped into another tank known as a secondary fermentation or brite tank after the fermentation process is largely complete.

A brite tank allows the beer to further clarify and carbonate before being transferred into a bottle, can or keg for consumption. Some brewpubs also serve beer directly from a brite tank.

Kegs

Brewers still need kegs for storing beer, even if they eventually transfer it to bottles or cans. They may also sell or serve beer in kegs to bars and restaurants, or serve it directly from kegs in a brewpub.

Kegs also need to be washed to prevent beer from spoiling or tasting bad. Smaller breweries may be able to get away with washing kegs by hand, but larger ones will prefer the greater efficiency and reduced costs of a keg washer.

ESTIMATING THE COST OF BREWERY EQUIPMENT

From equipment costs to brewhouse size, building expenses and licensing, the cost of running a brewery can range drastically based on your specific operation.

When estimating the price of your investment, it’s important to consider the cost of brewery equipment for your brewing operation. Fortunately, there are various types of equipment in which to choose as well as brewery equipment financing options to help you get off the ground and running.

11000L BREWERY configurations (Reference)

| 1.Malt Milling System | Mill machine | Stainless steel/Carbon steel |

| Grist case | Stainless steel |

| Flexible conveyor | Outer PPR or Stainless steel |

| 2.5000L Brewhouse System | Mash tun | Inner:3mm;outer:2mmMotor agitationSteam jackets/Electric elements/Fire direct heating |

| Lauter tun | Inner:3mm;outer:2mmRack system;False bottom filter |

| Kettle tun | Inner:3mm;outer:2mmSteam jackets/Electric elements/Fire direct heating |

| Whirlpool tun | Inner:3mm;outer:2mmSide tangent whirlpool inlet |

| Hot water tank | Inner:3mm;outer:2mmSteam jackets/Electric elements/Fire direct heating |

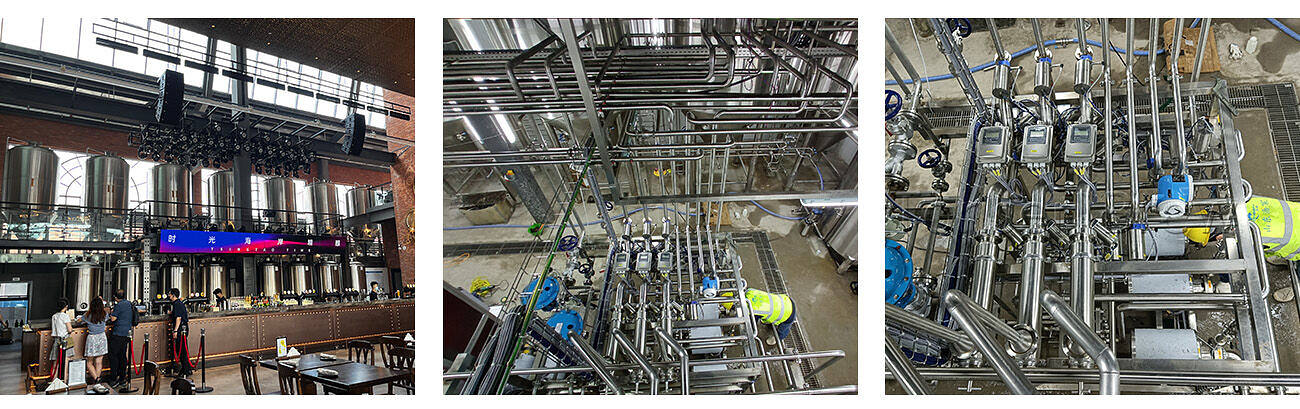

| Accessories | Mash pump;;Heat exchange plate;Hop back system; Brewhouse Pipes; |

| 3.Fermentation System | Fermentation tank | Pressure:3Bar;Inner:3mm;outer:2mm;with insulation;Cooling jackets; |

| Accessories | Yeast adding Tank; |

| 4.Cooling System | Glycol water tank | Inner:3mm;outer:2mm |

| Accessories | Chiller; Glycol water pump; Pipes and Valves; |

| 5.CIP System | Acid tank | Pump; Pipes and Valves |

| Disinfection Tank |

| Trolley |

| Accessories of the CIP System |

| 6.Control System | Automatic/Semi-auto |

| 7.Filtering System | Candle type diatomite filter/Membrane filter/Bag filter |

| Bright beer tank | Double-layer with insulation; |

| 8.Filling System | Glass bottle line | Capacity:800-1200 BPHWashing heads:8;Filling heads:8;Capping heads:3Optional:Capacity:1500-2000 BPHWashing heads:16;Filling heads:16;Capping heads:6 |

| Canning line | Capacity:1000-1500 CPHFilling heads:12;Capping heads:1 |

| Keg system | Keg filling machine;Keg washing machine;Keg washing and filling unity machine; |

10000L BREWERY configurations (Reference)

1.10000L Brewhouse

1)Mash Tun / Lauter Tank & Brew Kettle/Whirlpool Tank (2 Vessel)

2)Mash Tun & Lauter Tank & Brew Kettle/Whirlpool Tank(3 Vessel)

3)Mash Tun / Lauter Tank & Brew Kettle & Whirlpool Tank(3 Vessel)

4)Mash Tun & Lauter Tank & Brew Kettle & Whirlpool Tank(4 Vessel)

5)Mash Tun & Lauter Tank & Brew Kettle & Whirlpool Tank & Rice Cooker(5 Vessel)

Four-vessel systems offer the highest throughput and the most versatility. With proper vessel sizing, well laid out hard piping, and well-designed controls these brewhouses can be extremely large and only require one person to operate it. The ability to make more beer with less labor input, paired with gains in efficiency and quality control make the four-vessel brewhouse a worth while investment for breweries that intend to produce a lot of beer.

1) Fully insulated mash tun and brew kettle mounted on a modular, radius edge, stainless steel under-frame, designed for easy and efficient installation in almost any structure.

2) 100% certified SUS304 sanitary food grade stainless steel in all of our components.

3) False bottom/Sieve plate Equipped in Lauter tank,Laser milling, Filter gap: 0.8mm

This filter plate is made on a complete stainless by CNC lathe, it is strong, filter fast and leak no any grist. Which has a good effect in Separating wort and impurities. Grain door and False Bottom for rapid and efficient cleanup.

4) A Design that allows infinite control, endless flexibility and precise repetition.

5) All necessary equipment to monitor the quality of the brew.

6) Steam, Electric or Direct Fire for heating.

2. 5000L Fermentation System

Fermentation tanks are where the magic happens. It’s important to have a precisely built vessel to condition your beer as it ferments. Tonsen brew offers fermentation tanks with ultra-precise welding and polishing, complete traceability, and material exactness to meet all international safety standards. From small, pub-size fermenters to towering outdoor tanks, we have the manufacturing capability and expertise to custom-build fermentation tanks of all sizes.

Material: Stainless steel 304

Insulation: Polyurethane, TH: 100mm

Glycol jacket: Dimpled jacket on the cone and side

Or single wall with jacketed,or single layer fermentor.

Head: Double or single dish head on the top

Accessories: Sample valve, pressure gauge, solenoid valve, pressure relief valve, racking arm, CIP arm and Blow off arm, dry hops port and so on.

3. Tonsen Brew Auxiliary equipment

Tonsen Brew offers all necessary peripheral equipment to ensure that your brewery / Brewpub has everything it needs for a high quality brew and the means to give your clients the best drinking experience.

1)Malt Miller

Double Roller

Adjustable roller width, little dust, low noise

2)Cooling system

Glycol Tank

Chiller machine

3)CIP system

Disinfection Tank

Alkali Tank

4)Control Cabinet

Schneider low voltage electrical components; Danfoss VFD;

Wiring diagram will be provided with the panel;

wiring diagram and English nameplate.

All motors must have fuse and overload protection.

5)Packing system

Bottling

Canning

Kegging